Athens, GA |

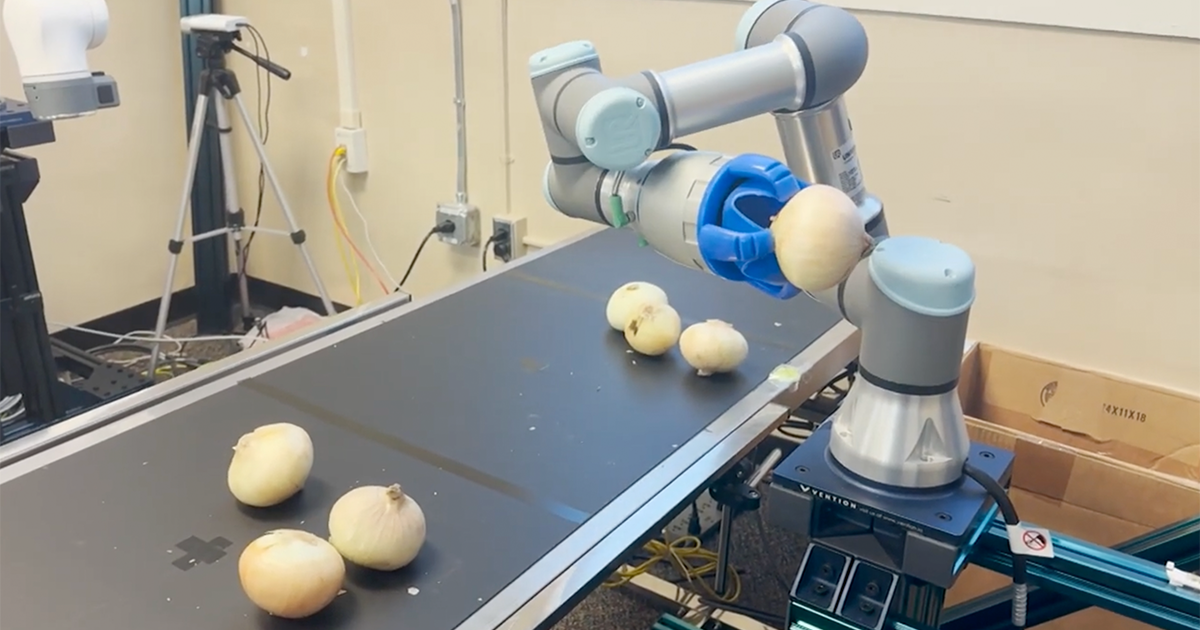

Between the use of GPS and auto-steering on tractors, to sensors and monitoring systems on irrigation pivots, precision agriculture has become an interregnal part of maximizing efficiency on the farm. And the next evolution could be the addition of robotics onto farming operations like this onion sorter Preshant Doshi and his team at the University of Georgia have been working on for the past six years.

“So, essentially, the robot is engaging in what I call as pick, inspect, place. So, the idea is that the robot has to figure out where to go in to pick the onion. This is told by the robot’s vision system. Then, once it picks the onion, it will process it and then based on what it sees, it will then either place the onion back on the conveyor or it will place it in the discard bin,” says Preshant Doshi, Professor of Computer Science at the University of Georgia.

This technology is not designed to replace humans, but rather work alongside them, which provides an interesting challenge when programing its safety measures.

“You need to first sense the human, where the human is, what he is doing, so, detect what actions he is doing. Then estimate what he might do next. Predict that and then adjust your behavior according to that. So, this is not a trivial thing at all, and humans don’t follow a fixed behavior. You cannot preprogram this into the robot. There is no one specific way in which humans sort something. So, there are a lot of challenges,” says Prasanth Suresh, Senior PhD Candidate at UGA.

Unlike the manufacturing industry, this smaller robot is designed to fit in around the farmer’s packing shed or warehouse, which provides a more cost-effective opportunity for them to check out some of the benefits this technology can provide.

“We essentially want to give them an option to be able to use robotic technology to do the sortation. So, there are off seasons and there are on seasons, for these farms, but during off seasons, they may still get shipments of onions and they may not have their full workforce around. At that point, you can actually use this technology and to be able to sort those onions. Also sometimes workers get sick, and they are not able to come in, but you still have to sort your onions. So, then again, you can lean on this technology to fill that gap,” says Doshi.

This type of system might be closer than you think, as Doshi hopes to have robots like this up and running over the next few years.

“The end goal is to be able to move this from the lab to the factory floor, to the packing shed floor. Once we are able to get our first deployment, then I think there will be a better awareness of what this technology can do and how it can work for you. I am really hopeful that in the next five years to see at least, some of the biggest sheds in Georgia start using this technology,” says Doshi.

By: Damon Jones